EA-A20 Hot Air BGA Rework System

- One-touch solder removal and one-touch chip placement.

- Zero-pressure chip placement.

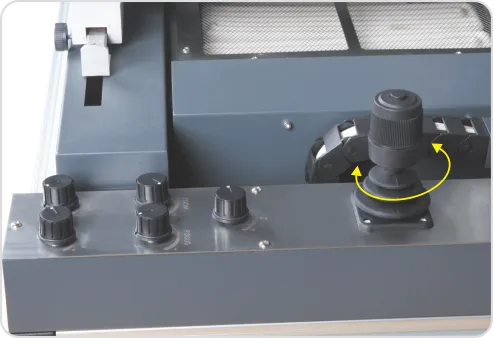

- Electric joystick motion control.

- Dedicated software interface for operation.

Contacts

Features

- High automation: single-button operation for soldering, repairing, picking, and placing chips; easy to use.

- High-power brushless DC fan, closed-loop sensor, zero-trigger microprocessor control; provides strong airflow at stable temperature. No external gas source needed; flexible application.

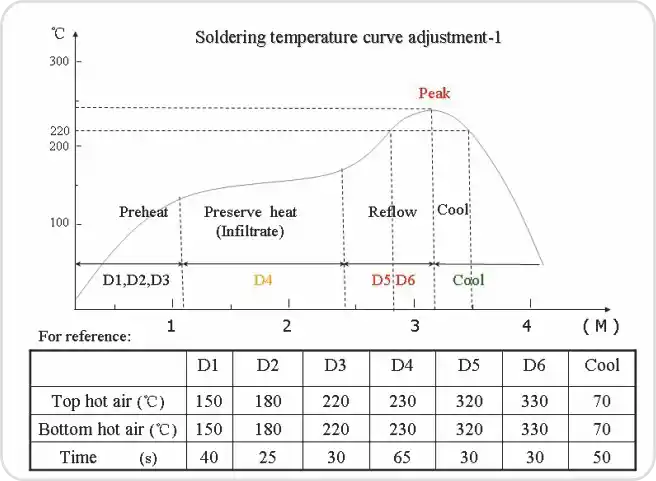

- Seven temperature zones suitable for reflective BGAs, multi-layer BGAs, metal shielded packages, and POP components.

- Integrated design: heating and alignment system work in perfect coordination.

- Two-color optical prism alignment with joystick control for precise positioning.

- Adjustable horizontal airflow fan; cools bottom heat zones and PCB according to process requirements.

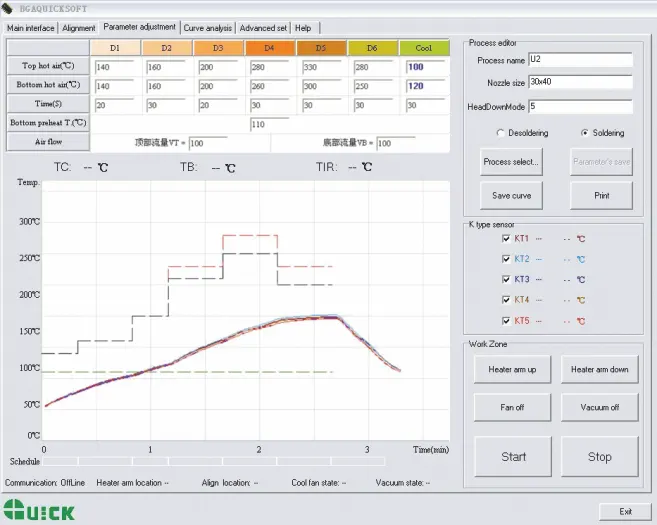

- QUICKSOFT interface with access rights for operation and profile analysis; allows analysis of preheat speed, peak temperature, soak time, and cooling rate.

- Multiple interchangeable nozzles.

- Compatible with desktop motherboards, server motherboards, industrial PCs, terminals, and large PCBs requiring BGA or CONNECT repair.

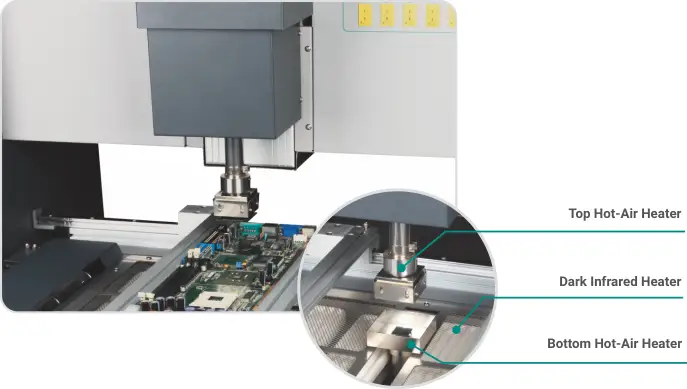

Heating Method

Temperature Control Features

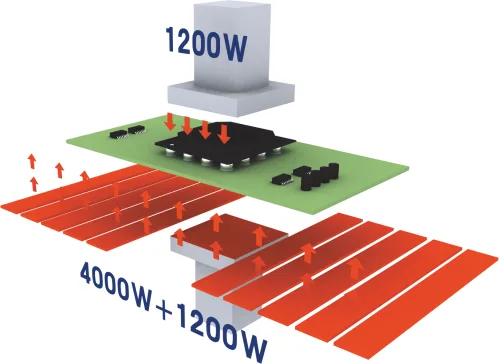

- Top and bottom heaters up to 1200W, combined with a brushless fan creating vortex airflow at 60L/min.

- Wide-area bottom infrared heater meets preheat requirements for large server motherboards and industrial PCs.

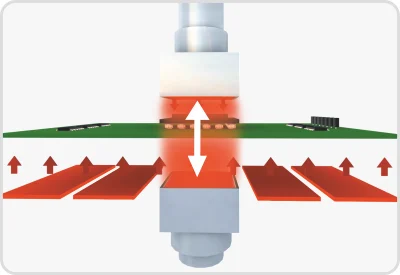

Vertical temperature difference control

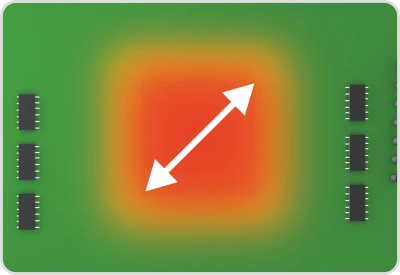

Horizontal and vertical temperature differences in the soldering zone are optimized for lead-free processes. Thanks to the specially designed hot-air convection system, soldering success rate and quality are ensured.

Horizontal temperature difference control

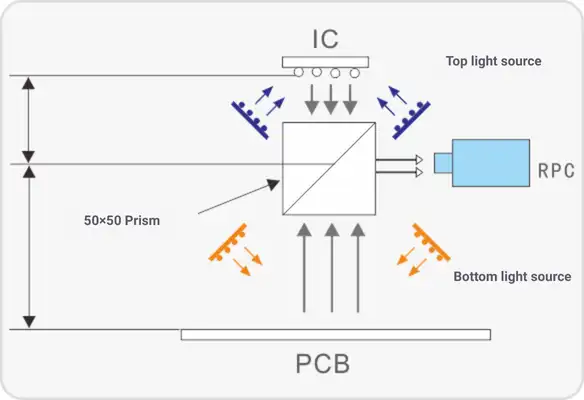

Optical Prism Alignment

Uses image-splitting prism for precise component positioning, with independent top and bottom illumination. Combines manual and automatic operation with ±0.02 mm alignment accuracy.

CCD Imaging

High-resolution autofocus camera with assistive lighting for clear, high-contrast images.

Optical Alignment Adjustment

During alignment, fine adjustments along X, Y, Z axes and θ angle can improve alignment efficiency by up to 50%.

Main Heater

- Heating structure with top, bottom, and middle hot-air zones, combined with bottom dark infrared heater for easy attainment of target thermal profiles.

- Adapts to various soldering conditions; reduced temperature differential helps achieve higher soldering CPK.

Software

7-level temperature control (D1–D6 + Cool) can simulate an SMT oven thermal profile, achieving optimal process conditions.

Oven Temperature Profile Analysis

The machine can be controlled via PC using BGA SOFT software, allowing thermal profile adjustment, parameter setting, and component height adjustment.

The software also enables analysis of key process parameters including preheat rate, peak temperature, soak time, and cooling rate.

Specifications

| Parameter | EA-A10 | EA-A20 |

|---|---|---|

| Total Power | 4200W (Max) | 6600W (Max) |

| Power Supply | 220V AC 50Hz | 220V AC 50Hz |

| Hot-air Temperature | 400℃ (Max) | 400℃ (Max) |

| Bottom Preheat Temperature | 400℃ (Max) | 400℃ (Max) |

| Top Hot-air Heater Power | 1200W | 1200W |

| Bottom Hot-air Heater Power | 1200W | 1200W |

| Bottom Infrared Heater Power | 1600W | 4000W |

| Hot-air Flow Rate | 60L/s | 60L/s |

| Bottom Infrared Preheat Area | 310×260mm | 530×405mm |

| Maximum PCB Size | 420×450mm | 600×650mm |

| Chip Size Range | 2×2mm–60×60mm | 2×2mm–60×60mm |

| Placement Accuracy | ±0.02mm | ±0.02mm |

| Placement Force | 1.5N / Non-contact placement (two modes) | 1.5N / Non-contact placement (two modes) |

| Adjustable Side Cooling Fan Flow | ≤3.5 m³/min | ≤3.5 m³/min |

| Magnification | 36×12 | 36×12 |

| Horizontal Resolution | 500 lines | 500 lines |

| Camera | PAL system (progressive inversion) | PAL system (progressive inversion) |

| LED Illumination | White light (adjustable brightness) | White light (adjustable brightness) |

| External K-type Thermocouple | 5 channels | 5 channels |

| Interface | USB | USB |

| Dimensions (D×W×H) | 810×675×835mm | 1200×800×940mmEA-A10 Hot Air BGA Rework System |