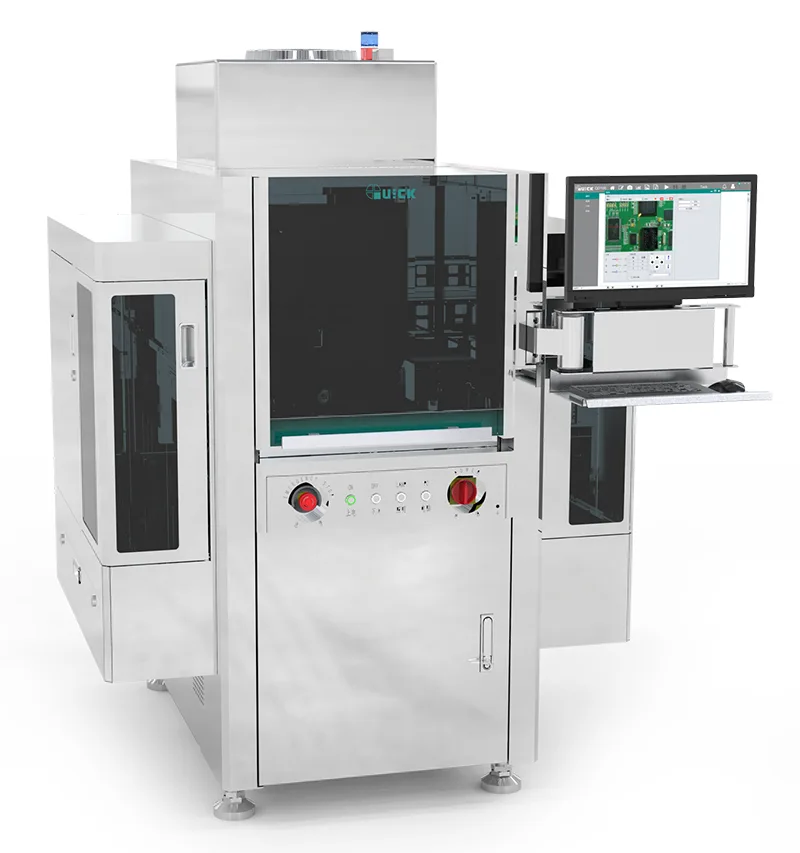

Precision dispensing

|

Linear/servo motor drive |

On-line QR code scanning is available |

|

Adsorption/heating module |

Integrated visual system |

|

MESData interaction |

AVIdetection of glue track |

Providing high-precision dispensing and automated material delivery systems for electronics manufacturing, precision engineering, medical applications, and industries requiring accurate control of liquid, adhesive, or bonding material dosage. These dispensing systems enhance efficiency, reduce material waste, and ensure consistent product quality.

Main product categories:

- In-line precision dispensing equipment: Systems directly integrated into production lines, enabling continuous and automated dispensing, ideal for high-volume manufacturing.

- Benchtop observation dispensing systems: Compact benchtop machines that allow direct observation and manual adjustment of dispensing volume, suitable for laboratories, prototyping, or small-scale production.

- Fully automatic dispensing equipment: Fully automated, program-controlled systems designed to deliver materials with high accuracy, minimizing errors caused by manual operation.

- Cleanroom dispensing systems: Specialized designs for cleanroom environments, minimizing dust and contaminants to ensure dispensed materials remain perfectly clean.

- Pieza-driven jet valves: Piezoelectric jet valves capable of dispensing extremely small and precise material volumes, suitable for high-tech adhesives, inks, or specialty liquids.

- Precision screw dispensing valves: Screw-driven mechanisms that deliver a stable and consistent material flow, ensuring uniformity and accuracy for demanding applications.

- Glue re-inspection to eliminate batch defects

- Fully automated magazine-type loading and unloading

- Product shape recognition without mark-based positioning

- Angled dispensing to meet multi-angle application requirements

- Feed table status detection to prevent collisions caused by product deformation

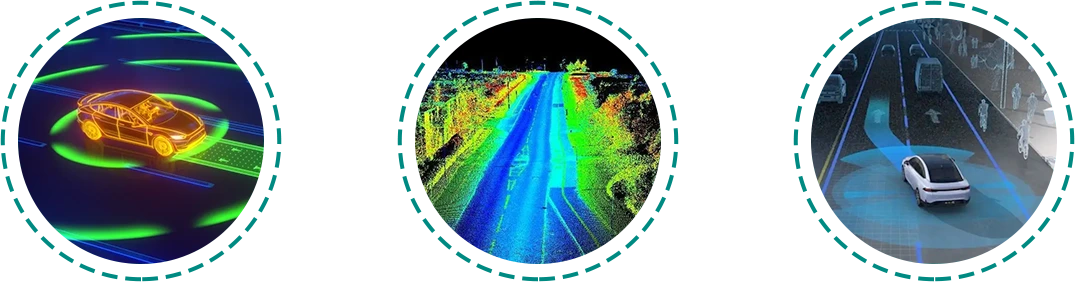

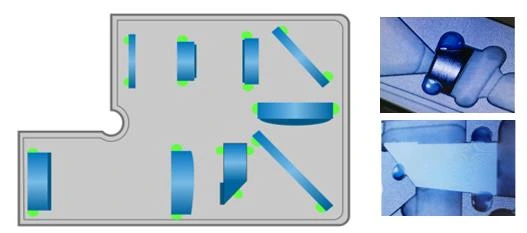

Industrial applications of fixed dispensing for LiDAR lenses

- Dispensing UV adhesive for multiple lenses at various positions.

- High-quality dispensing, ensuring no diffusion and no adhesive overflow.

- The dispensing requirements across different fixture surfaces must be considered due to significant variations between product jigs. A laser height measurement system is equipped to ensure dispensing stability.

- Capable of supporting multi-product manufacturing with fast and flexible line changeovers.

- The equipment meets Class 100 cleanroom standards.

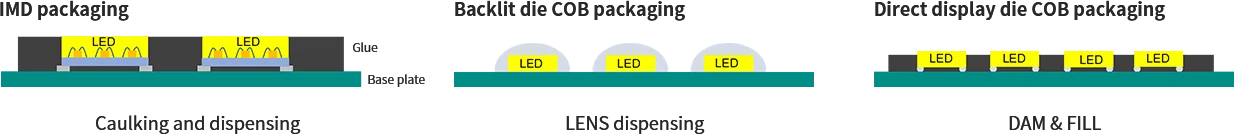

DAM & FILL

👉 Box dam & Filling process

👉 Previous process: die bonding+reflux

LENS

👉 Lens dispensing process

👉 Previous process: die bonding+reflux

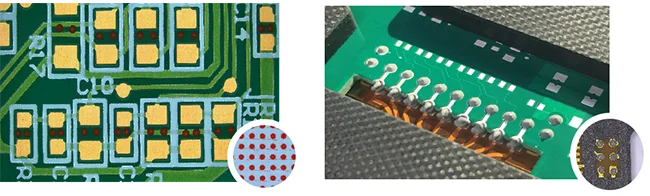

Dispensing flux / Solder paste

👉 FPC and PCB before soldering: Conduct Flux & Solder paste dispensing process.

👉 Subsequent process: FPC hot pressure soldering

FPC reinforcement

👉 FPC UV reinforcement technology

-

Mold-proof, salt-spray resistant, and moisture resistant.

-

Component reinforcement to improve vibration and impact resistance.

-

Reinforcement of component leads / solder joints (fillet weld legs / pins) to enhance mechanical stability.

- Adhesive must not contaminate restricted areas, and the allowable overflow width must be strictly controlled.

-

In the overall packaging (encapsulation) process, the component must be fully covered with adhesive, with no gaps or exposed areas.

-

Component leads / solder joints are treated as part of the encapsulation process, and the leads/joints must be completely coated with adhesive.

- Dispensing methods: unilateral / L-type / U-type.

- Adhesive volume control: plan dispensing paths to precisely control the adhesive volume.

- Cycle-based control: dispensing repeated at fixed time intervals.

- Rotary-angle dispensing: meets requirements for narrower adhesive lines (reduces overflow).

- Red adhesive dispensing process is primarily used to enhance component adhesion, prevent component shifting or dropping during reflow, and increase the stability of large components. It is mainly applied in SMT mounting and wave soldering processes.

- Solder paste dispensing is a pre-soldering process, mainly applied to: paste dispensing before SMT component placement and PCB soldering; FPC–FPC soldering and FPC–PCB soldering; Paste-In-Hole (PIH) processes for through-hole components (PTH) on FPC and PCB; and processes where stencil printing is not feasible due to space constraints or component geometry.

- Adhesive volume control ensures uniform adhesive application and consistent quality even when equipment operates at high throughput.

- Equipment stability meets the requirements for high-speed flight operations.