6612 Fume Extractor

- Intelligent closed-loop airflow control

- Connects to the soldering station for smart operation and sleep mode

- High-power brushless motor

Contacts

Features

- Smart airflow control: Closed-loop control ensures stable suction and saves consumables.

- Intelligent peripheral devices (e.g., soldering robots / smart soldering stations) can control system operation and standby mode, improving energy efficiency.

- Smart brushless motor speed control, extending motor lifespan and efficiency.

- Unique vortex fan design, providing stronger suction.

- Detachable filter design, prolonging filter life and reducing consumable costs.

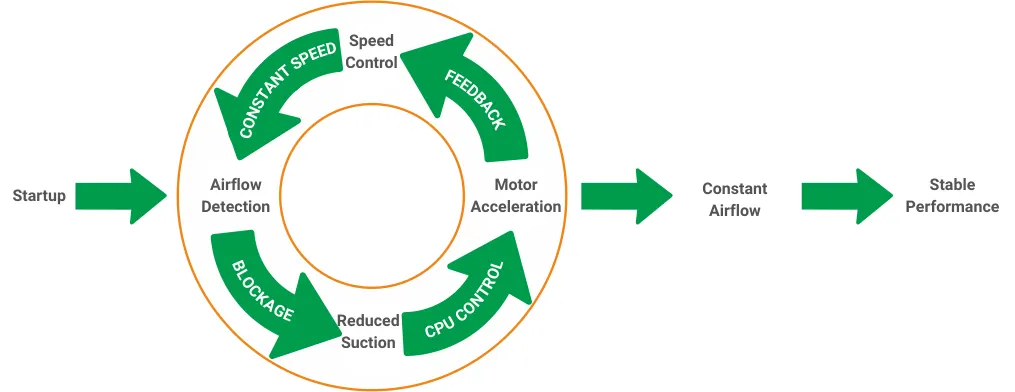

Airflow Control

Closed-loop airflow control ensures stable suction and saves consumables.

Three Alarm Functions

Newly added flow sensors and real-time motor speed control ensure stable airflow and consistent filtration performance.

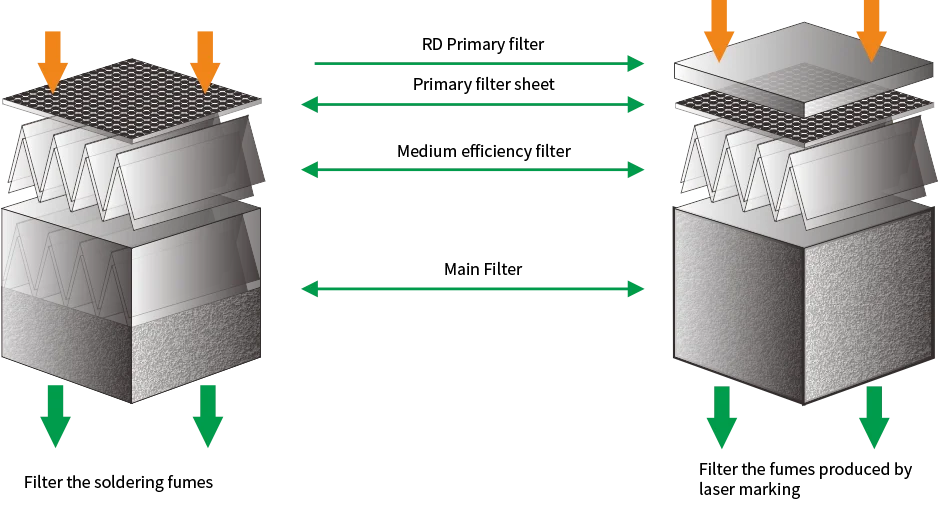

Smoke Filter

First, harmful solder fumes pass through the primary filter to remove large particles. Then the fumes pass through medium-efficiency and high-efficiency filters, removing 99.97% of particles >0.3 µm in the airflow. This is a fiberglass filter system. This stage is mainly physical filtration. Another stage uses a fine air filter, combining physical and chemical processes. This air filter primarily treats ultrafine particles and volatile organic compounds (VOCs) using the physical adsorption property of activated carbon combined with chemical materials, neutralizing exhaust safely.

Comparison

Traditional duct smoke extraction – Disadvantages

- Direct discharge to the outside: Traditional duct fans release polluted air outdoors, causing environmental pollution and not meeting environmental protection requirements.

- Energy waste: Traditional ducts exhaust cold or hot air at hundreds to thousands of m³/h, overloading HVAC systems and wasting energy. The KuaiKe Fume Extractor uses an indoor circulation system.

- Fixed and inflexible: Traditional ducts are stationary, not movable, unsuitable for production line rearrangements.

- No independent control: Traditional duct fans run at full power for the entire workshop, cannot be switched on/off for individual stations, wasting energy.

- Reduced efficiency over time: Dust and solder residue accumulate in ducts, reducing suction efficiency and creating potential safety risks.

| Item | Smart Fume Extraction System | Conventional Smoke Filter |

|---|---|---|

| Flow | Stable airflow, strong suction, continuous filtration. | Suction decreases over time, reduced filtration efficiency. |

| Cost | Smart airflow control and detachable filter design → long filter lifespan. | Average filter lifespan, frequent replacement. |

| Connectivity | Intelligent peripheral devices control system operation and standby mode, saving energy and convenient. | Separate control required, less convenient operation. |

| Lifespan | Brushless motor with sensor monitoring, smart speed adjustment, low noise, long lifespan. | Standard motor, noisy, runs continuously at high speed, short lifespan. |

Performance Chart

Applications

- Soldering iron workstations

- Solder pots, wave soldering, reflow ovens

- Laser soldering, engraving, marking, cutting

- Chemical labs, medical, beauty

Specifications

| Item | QUICK 6611 | QUICK 6612 |

|---|---|---|

| Number of stations | 1 | 2 |

| Static pressure | 2400 Pa | 2800 Pa |

| System airflow (including filter) | 100 m³/h | 2 × 100 m³/h |

| Filtration efficiency (0.3 µm) | 99.97% | 99.97% |

| Power | 120 W | 250 W |

| Noise | < 60 dB | < 65 dB |

| Voltage | AC 220V | AC 220V |

| Dimensions | 420 × 230 × 430 mm | 470 × 230 × 500 mm |

| Linking function | Yes | Yes |

| Flow controller | Yes | Yes |

| External controller | Smart control | Smart control |

| Weight | Approx. 13.4 kg | Approx. 15.5 kg |

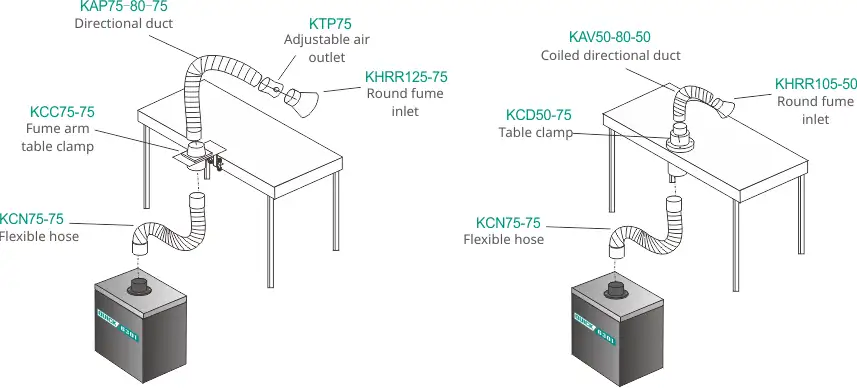

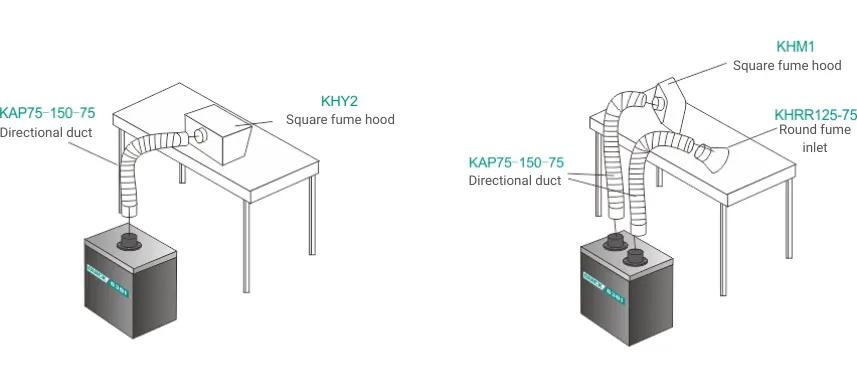

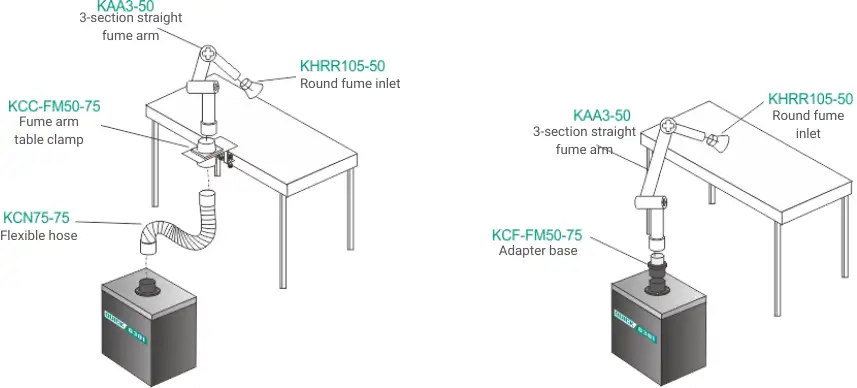

Installation Method