EA-H15 Infrared BGA Rework System

- IR infrared reflow soldering system

- PL precision alignment and placement system

- RPC reflow monitoring camera

Contacts

Features

- Infrared (IR) Reflow System: Direct infrared temperature sensor measures the BGA surface temperature to implement true closed-loop control, ensuring accurate thermal windows and even heat distribution.

- Precision PL Alignment System: High-resolution optical prism alignment is used to overlay solder balls and pads; scientific, precise, simple control for easy component placement and removal.

- RPC Reflow Monitoring Camera: Observe the melting process of BGA solder balls from multiple angles, supporting precise and reliable process curve monitoring.

- BGASOFT Control Software: Connects to a PC to record, control, and analyze the entire process, generating thermal curves that meet modern electronics requirements.

- CONTROL BOX Keyboard: Multifunctional control keyboard makes continuous rework more efficient and easier.

Heating & Temperature Control

Long-wave infrared (dark IR) heating combined with a non-contact infrared sensor monitors the BGA surface temperature in real-time, implementing closed-loop control to ensure accurate thermal windows and uniform heat distribution.

Top Heater

The top heater uses a 720 W infrared heating bar with a medium wavelength (2–8 μm). The heating window size can be adjusted according to BGA size. At the end of the process, the integrated vacuum bar automatically lifts the BGA chip and places it on top of the fan for cooling. No hot air nozzle is needed, reducing costs.

Bottom Heater

Four long-wave infrared ceramic heating discs with a peak power of up to 1600 W are used. The base size is expanded, allowing preheating of larger PCBs while ensuring uniform temperature distribution and preventing localized overheating, warping, and deformation.

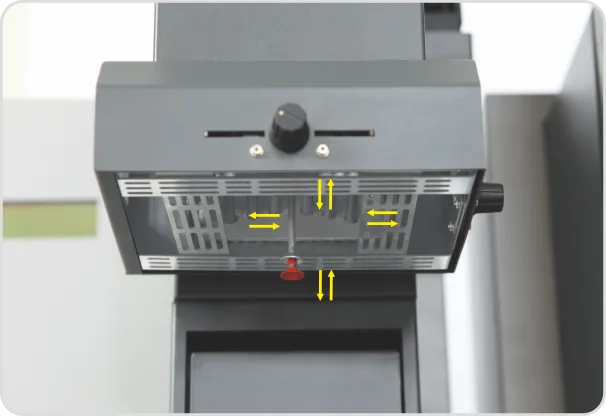

Optical Prism Alignment

Uses separate image prism alignment. BGA solder balls are illuminated with blue light, PCB pads with orange light, with adjustable intensity. The dual-color light is refracted through the prism, displaying clear images of BGA balls and PCB pads. Using the PL camera, the balls and pads are clearly shown on the screen. Fine-tuning knobs for X, Y, Z and 0° angle allow perfect alignment. One “Place” press completes the operation.

Alignment Adjustment

During alignment, fine-tuning knobs X, Y, Z, and angle e ensure maximum precision. Easy handling for components with 0.4 mm pitch.

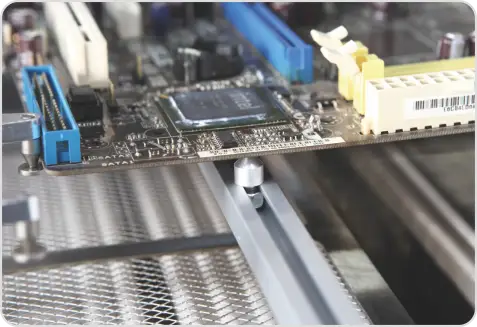

PCB Clamping

Uneven PCBs can be secured horizontally with various fixtures, while large PCBs are supported from below using anti-drop pins to prevent deformation.

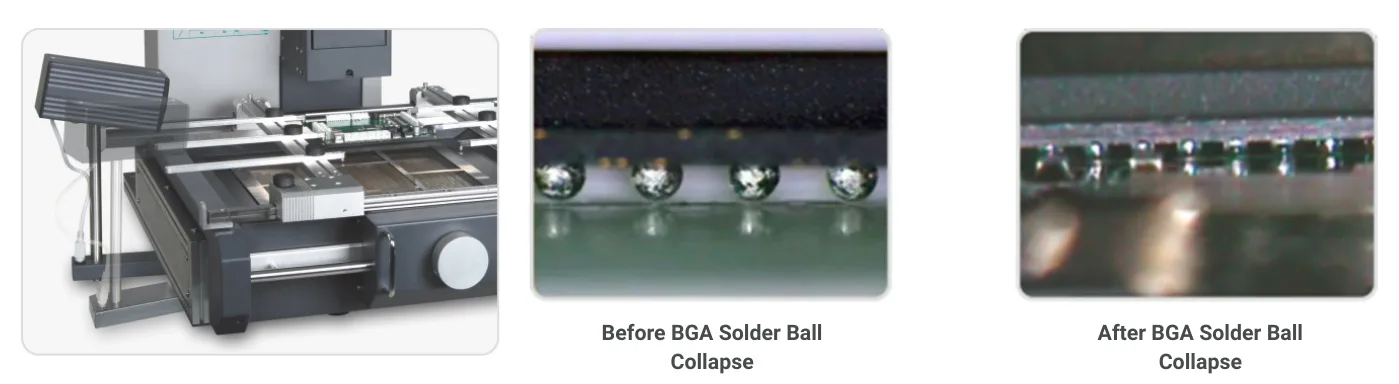

RPC Reflow Monitoring Camera

The RPC reflow monitoring camera observes BGA solder ball melting, sinking, and joint formation from multiple angles during reflow. The RPC can be adjusted and moved for various viewing angles.

Infrared BGA Reflow System (IR)

| Parameter | Value |

|---|---|

| Total Power | 2800 W (Max) |

| Power Supply | 220V AC 50 Hz |

| Bottom Preheat Power | 400 W × 4 = 1600 W (long-wave IR emitters) 400 W × 6 = 2400 W (optional high-resolution IR bars) |

| Top Preheat Power | 120 W × 6 = 720 W (IR bars, wavelength 2–8 μm) |

| Top Heater Size Range | 20 – 60 mm (adjustable X, Y direction) |

| Bottom Preheat Area | 290 × 290 mm |

| Maximum PCB Size | 390 × 420 mm |

| Interface | USB (PC connection available) |

| Temperature Sensor | Non-contact IR |

| Weight | Approx. 90 kg |

| Overall Dimensions | 850 × 720 × 730 mm |

Precision PL Alignment & Placement System

| Parameter | Value |

|---|---|

| Camera |

|

| Prism Size | 50 × 50 mm |

| Repairable BGA Size | 2 × 2 mm – 60 × 60 mm |

| Camera Output | Video signal |

RPC Reflow Monitoring Camera

| Parameter | Value |

|---|---|

| Camera |

|

| LED Support | Available |

| CONTROL BOX | Multifunctional operation keyboard |

| Video Capture Card | 4-channel analog video input |

| VIDEO SOFT | Professional video capture software |

BGASOFT

BGASOFT is the dedicated control software for QUICK EA-H15. It allows users to monitor temperature, analyze, adjust, and set thermal parameters for each process. The BGA reflow process typically includes five stages: preheat, soak, activation, reflow, and cooling. Temperature and ramp rates in the soak, activation, and reflow stages are critical.

- Preheat Stage: Medium-wave IR is efficiently absorbed by the PCB, ensuring uniform baseline temperature.

- Soak Stage: Eliminates temperature differences between components and between PCB and components, preventing PCB warping and component damage.

- Activation Stage: Maximizes flux activity to support soldering.

- Reflow Stage: Heaters ramp continuously to peak temperature, fully melting BGA solder balls to bond with pads and form intermetallic compounds.

- Cooling Stage: Top and side fans automatically activate at the end of the process; cooling speed is adjustable.

Software Features

- Password-protected login.

- Parameter protection password to control editing rights and ensure process reliability.

- Quick start function: press “Start” to execute the selected process.

- Thermal curve analysis: analyze and study processes based on saved temperature curves.

- View historical process parameters and thermal curves; compare different process curves.