Laser soldering

|

Precision quantitative soldering |

High reliability soldering |

|

Real-time closed-loop temperature control |

Constant voltage multi-point soldering |

|

Coaxial visual positioning |

Brazeless fusion soldering |

Providing ultra-high-precision automated soldering solutions designed for the electronics, optics, precision mechanics, and other industries that demand exceptional solder joint quality. Laser technology enables highly focused thermal energy at the soldering point, minimizing thermal distortion, enhancing joint strength, and ensuring outstanding stability in mass-production environments.

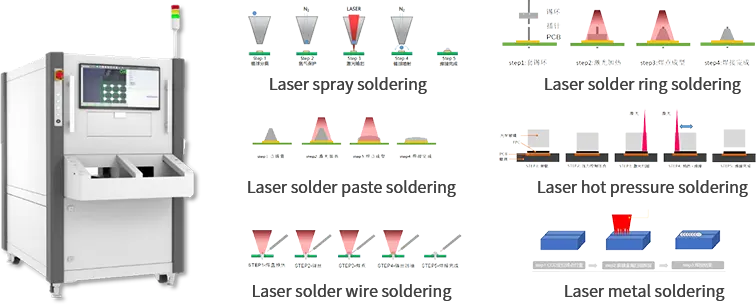

Our laser soldering systems support multiple methods such as laser solder jetting, laser solder paste reflow, laser wire soldering, laser preform soldering, laser hot-bar soldering, and laser metal welding. Each solution is engineered to suit specific product types, component structures, and process requirements.

Main Laser Soldering Technologies:

- Laser Solder Jetting:

Provides uniform and smooth solder deposition, ideal for fine-pitch, densely packed solder points or high-speed production. - Laser Solder Paste Reflow:

Delivers precise heating for stable paste melting, suitable for SMD components and applications requiring high process finesse. - Laser Wire Soldering:

Enables accurate solder volume control, producing clean, robust, and repeatable solder joints for automated manufacturing. - Laser Solder Preform Welding:

Ideal for circular parts or fixed locations, ensuring consistent and even solder distribution. - Laser Hot-Bar Soldering:

Combines pressure and laser heat to create high-strength joints, suitable for components with difficult-to-solder surfaces or high-reliability requirements.

- Laser Metal Welding:

A solution for thin metals, heat-sensitive materials, or high-precision structures where traditional welding methods fall short.

Laser soldering has the features of non-contact heating, small heat diffusion, high heating efficiency, barrier-avoidance soldering, quantitative solder supply, and high soldering yield for dense-pitch products, etc.

It is widely used in precision soldering fields such as 5G communication and optical communication modules, 5G communication circulators, CMM camera modules, and 3C smart device manufacturing, etc.

For 5G communication isolator/filter soldering, the company provides mature automation solutions with independent intellectual property rights, covering the product process from 5 mm to 10 mm.

In addition to conventional functions such as automatic loading, automatic positioning, automatic ranging, and laser soldering, the company also offers optional intelligent modules including the AOI module, MES module, and SPC module.

For the pain point of high-difficulty soldering of fiber cores, brackets, shields, and FPCs in data cables, the company takes the lead in providing comprehensive on-line laser soldering solutions for high-speed communication wires and optical communication modules and other related products.

The equipment adopts a modular design, enabling fast and flexible switching to produce a wide variety of products for customers.

The innovative laser soldering process effectively solves the soldering challenges of products such as optoelectronic modules, optical communication gateways and router cables, PC card and connector board cables, optical communication data center cables, server communication cables, and IoT data-center data cables, etc.